AM Solutions, a brand of the Rösler Group and Alfa Romeo Racing ORLEN take another step forward in the realm of technological innovation.

Click here to subscribe to our print edition!

As part of the agreement to bolster the team’s post-processing of additive manufactured part, Alfa Romeo Racing ORLEN will acquire three S1 systems by AM Solutions – 3D postprocessing technology to bring the automation, economic efficiency and repeatability of its post-processing to the next level.

AM Solutions is a brand created by Rösler, one of the world’s leading experts in surface finishing, to offer tailor-made products and services designed around the challenges and needs of additive manufacturing. With 3D printing having an increasingly profound effect on every aspect of industrial manufacturing, including that of a Formula One team, the edge is given by AM Solutions helps the team have access to industrial solutions for partial to fully automated postprocessing of polymer and metal additive parts for all printing technologies.

Several 3D printed parts feature on the Alfa Romeo Racing ORLEN C41, competing in the 2021 Formula One world championship, and the ability to have more precisely made items created in an efficient and cost-effective way will provide benefits to the team. The new S1 system for the automatic de-powdering and cleaning of small to midsize volumes of 3D printed parts offers numerous new technical features, such as a new basket design for optimal distribution and circulation of the parts, a specially developed wear protection lining made of non-staining anti-static polyurethane, ATEX conformity, and safe and ergonomic machine handling.

Stephan Rösler, President & CEO of the Rösler Group:

We are delighted to partner with Alfa Romeo Racing ORLEN in the field of post-processing of additive manufactured parts. As an early adopter of 3D printing, Sauber has recognized the importance of post-processing in terms of automation, cost-effectiveness and repeatability in the AM production chain. Their deep knowledge and experience will help us to further improve our solutions and to increase the awareness of our still young AM Solutions brand. We will bring our decades of know-how in surface finishing combined with our tailor-made solutions for the needs and challenges of AM to the track. By this partnership, we create a perfect win-win situation for two highly innovative companies, that always strive for the max.

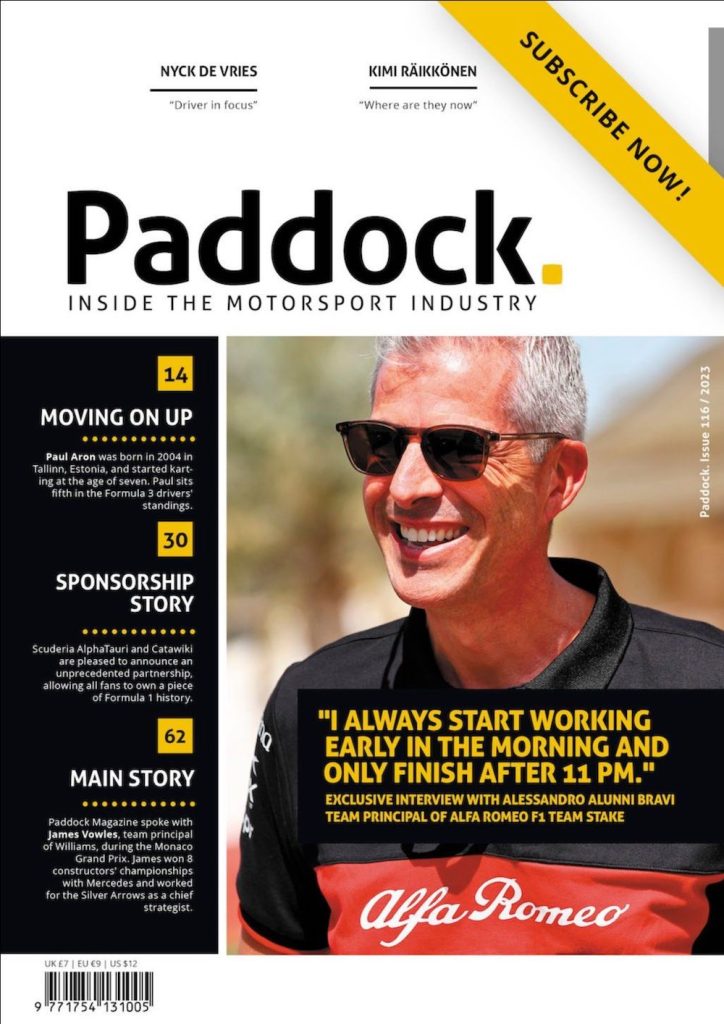

Frédéric Vasseur, Team Principal Alfa Romeo Racing ORLEN and CEO Sauber Motorsport AG:

Additive manufacturing is playing an ever-increasing role in Formula One and every new iteration of our race cars feature more 3D printed parts – in addition to those used in other operations of the company, from the wind tunnel models to experimental parts. The innovations brought by AM Solutions help us create parts quickly, more efficiently and with less waste, meaning we gain on time and money, two resources available in very finite amounts in our sport, while at the same time improving the sustainability of our operations. It’s all part of the marginal gains we make across every aspect of our operations as we move towards the front of the grid.

Related Articles